A brief analysis of the test purpose of the insulating oil breakdown voltage tester:

1.The dielectric strength of electrical insulating materials is the key performance that determines the conditions under which the material can be used. In many cases, the dielectric strength of the material is a decisive factor in the design of the device used.

2.This test method is used to provide part of the required information to judge the suitability of the material under certain application conditions; of course, it can also be used to detect changes in the process, the degree of aging, or other manufacturing or environmental conditions. Change or deviation from normal characteristics. The test method can be effectively applied to process control, verification or research testing.

3.The results obtained by this test method can rarely be directly used to judge the dielectric properties of materials in actual use. In most cases, it is also necessary to compare the results obtained from other functional tests and/or tests on other materials to estimate their impact on specific materials before evaluation.

4.When comparing different materials with each other, the results given by the test method are different without mentioning. If an electric voltage controller can be installed, the slow test method will be simpler and more commonly used than the stepwise test method. The results obtained by different test methods can be compared with each other.

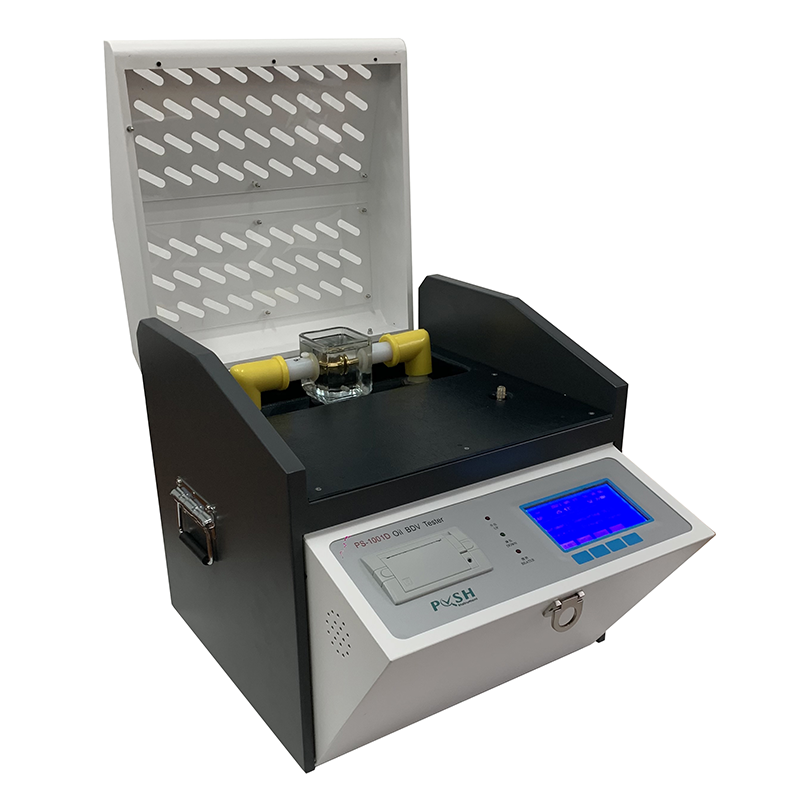

ps-1001 insulating oil dielectric strength tester complies with GB1986, GB2002, IEC156 standards, supports custom settings, and can adapt to multiple choices of different users; it is used to test the degree of physical pollution of insulating oil by water and other suspended substances. The measuring method is to put the test oil in the equipment and subject it to an alternating electric field that is evenly boosted at a certain speed until the oil is broken down. This instrument uses single-chip microcomputer as the core, uses large-scale integrated circuit, new I/O interface, realizes the test automation, and can be widely used in electric power, petroleum, chemical and other industries.

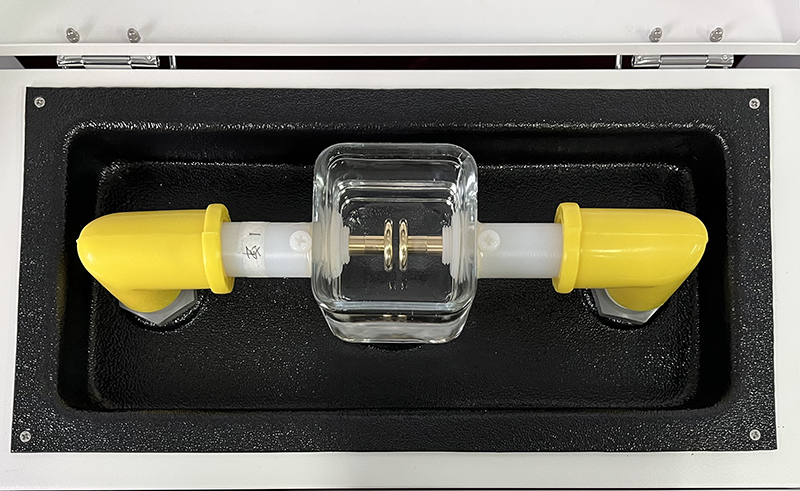

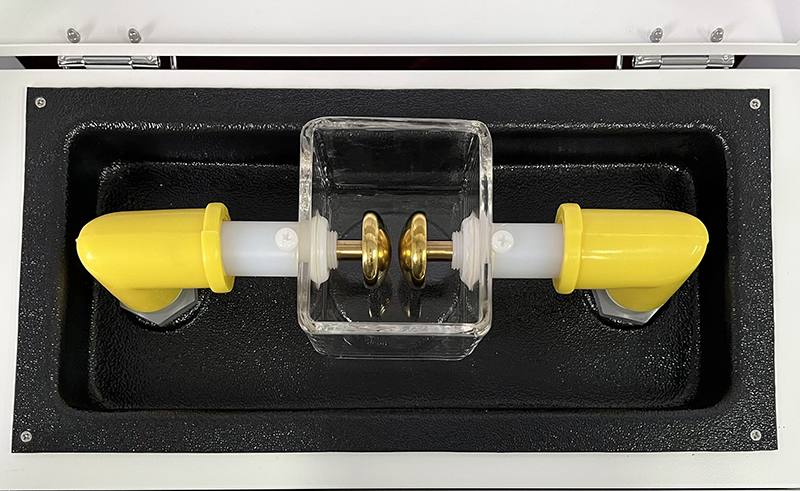

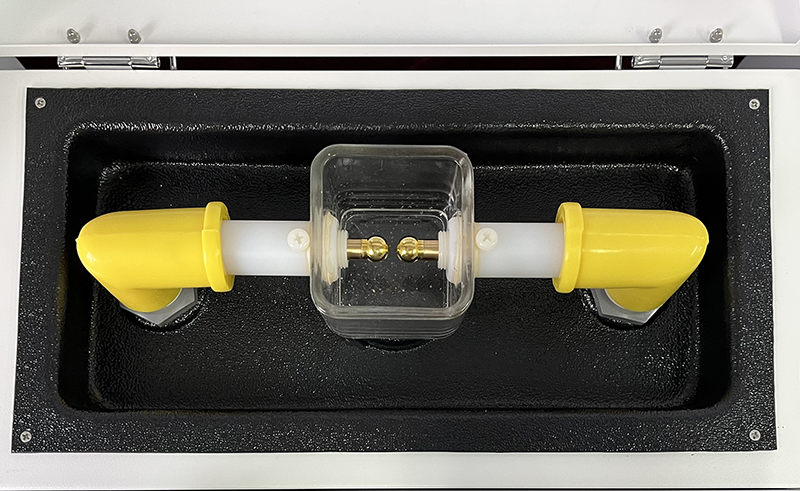

Optional electrode:

1. The instrument has a wide range watchdog circuit to eliminate the crash.

2. Disposable special glass mould for the instrument,

3. The unique high-voltage end sampling design of the instrument allows the test value to enter the A / D converter directly, avoids the error caused by the analog circuit and makes the measurement result more accurate.

4. Multiple protection functions, with strong anti-interference ability and good electromagnetic compatibility.

5. Single cup type, three cup type and six cup type are available

| Name Indicators |

| Output voltage 0~80 kV(or 0-100kV) |

| THVD <1% |

| Pressure rate 0.5~5.0 kV/s |

| Booster capacity 1.5 kVA |

| Measurement accuracy ±2% |

| Supply voltage AC 220 V ±10% |

| Power frequency 50 Hz ±2% |

| Power 200 w |

| Applicable temperature 0~45℃ |

| Applicable humidity <85 % RH |

| Width * height * depth 410×390×375 (mm) |

| Net weight ~ 32 kg |