The flash point is the lowest temperature at which a flammable liquid or solid can give off sufficient vapour to form a flammable mixture with air at the surface of the liquid or solid in the container used. The flash point of a flammable liquid varies with its concentration.

As the temperature increases, the vaporized oil and gas on the fuel surface increases. When the mixture of oil and gas and air reaches a certain concentration, when it comes into contact with it with an open flame, a short flash will occur (flicker and extinguish), and the oil temperature at this time is called for the flash point. The lighter the oil, the lower the flash point. The higher the flash point, the safer it is.

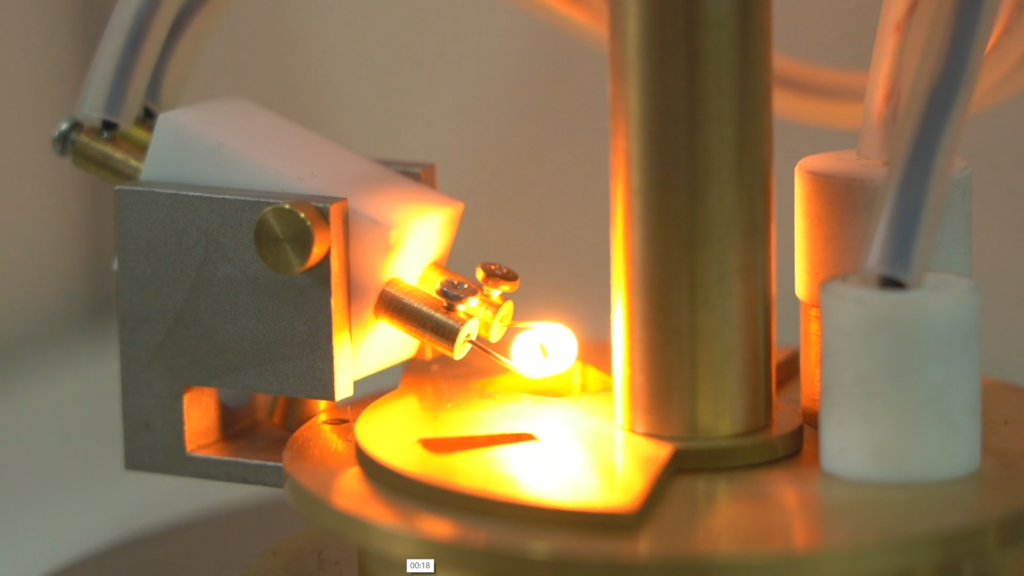

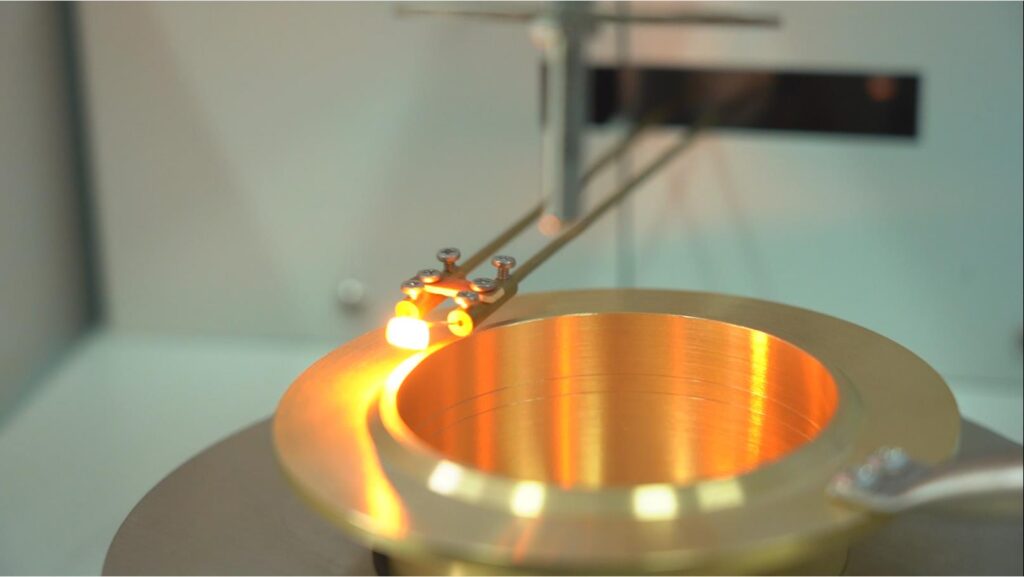

There are two methods for determining the flash point: the open cup method and the closed cup method. The result measured by the open cup is called the open flash point.(PS-KS403 Automatic Open Flash Point Tester); The result measured by the closed cup method is called closed flash point, (PS-BS303A automatic closed flash point tester). The open flash point is always higher than the closed flash point, because the oil vapor generated by the open flash point tester can freely diffuse into the air, and it is relatively difficult to reach the temperature that can be flashed. The flash point measured by the open cup method is 15-25 °C higher than that of the closed cup method.

Push Electric Manufacturing Co., Ltd. – a professional manufacturer and supplier of oil detection instruments.

As a professional manufacturer – Push Electric Manufacturing Co., Ltd. constantly absorbs the feedback information from the market, from the perspective of customers, it constantly improves the instruments and produces high-precision instruments that meet the needs of many domestic and foreign buyers.

As a professional supplier, Push Electric Manufacturing Co., Ltd. has continuously improved pre-sale, in-sale and after-sale management systems, including a product file management system that connects the manufacturing status of products with the status of products used by customers and lifetime maintenance, as well as the ability to A technical support team that meets the needs of the use process in a timely manner.

As a professional manufacturer and supplier,Push Electric Manufacturing Co., Ltd. is constantly improving itself for the sake of customers. In the life cycle from manufacturing and supplying to the user’s use of the instrument, the product quality management system, environmental protection and safety management system are always implemented in the whole process of product development, manufacturing, sales and maintenance, so as to create greater benefits for customers.