FEATURED PRODUCTS

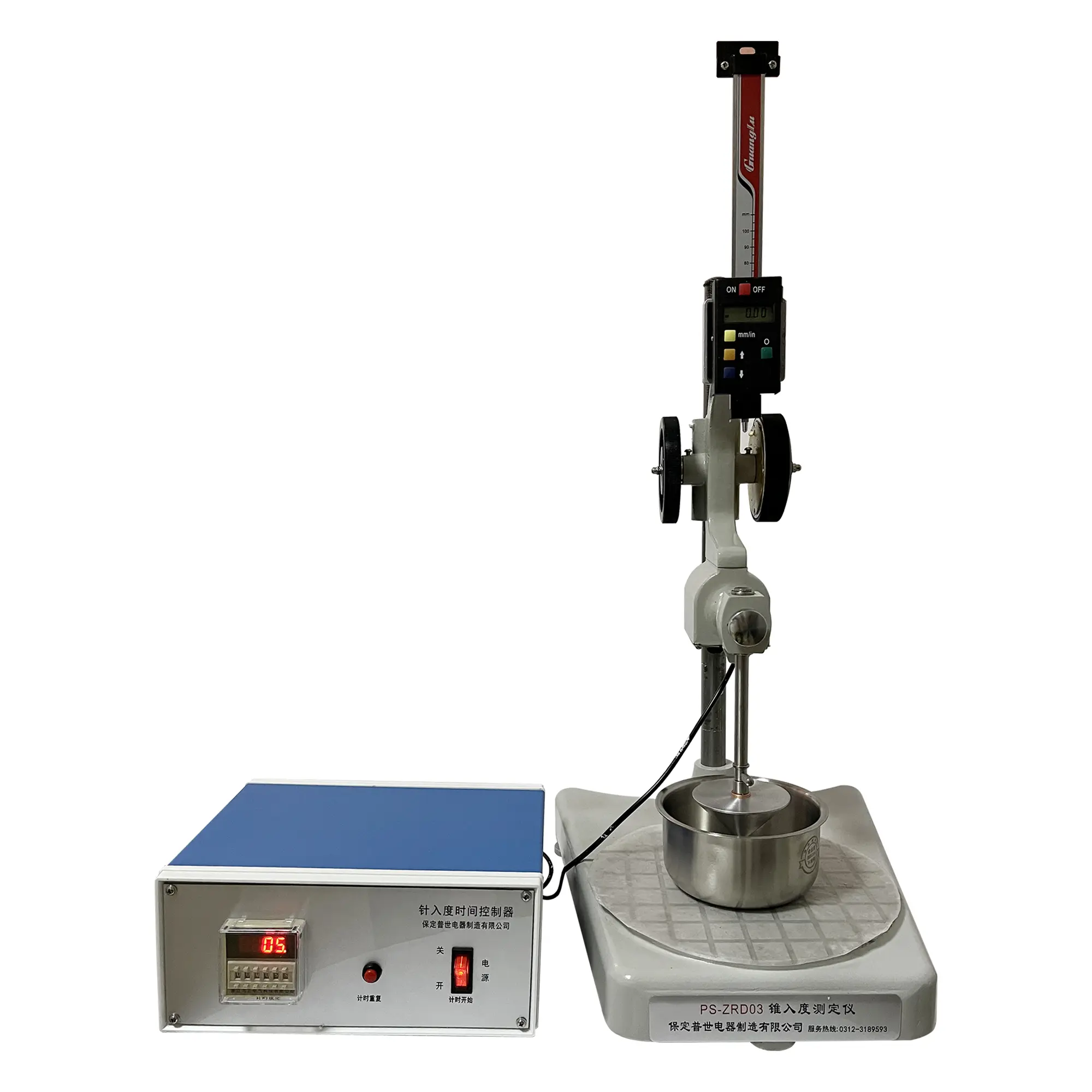

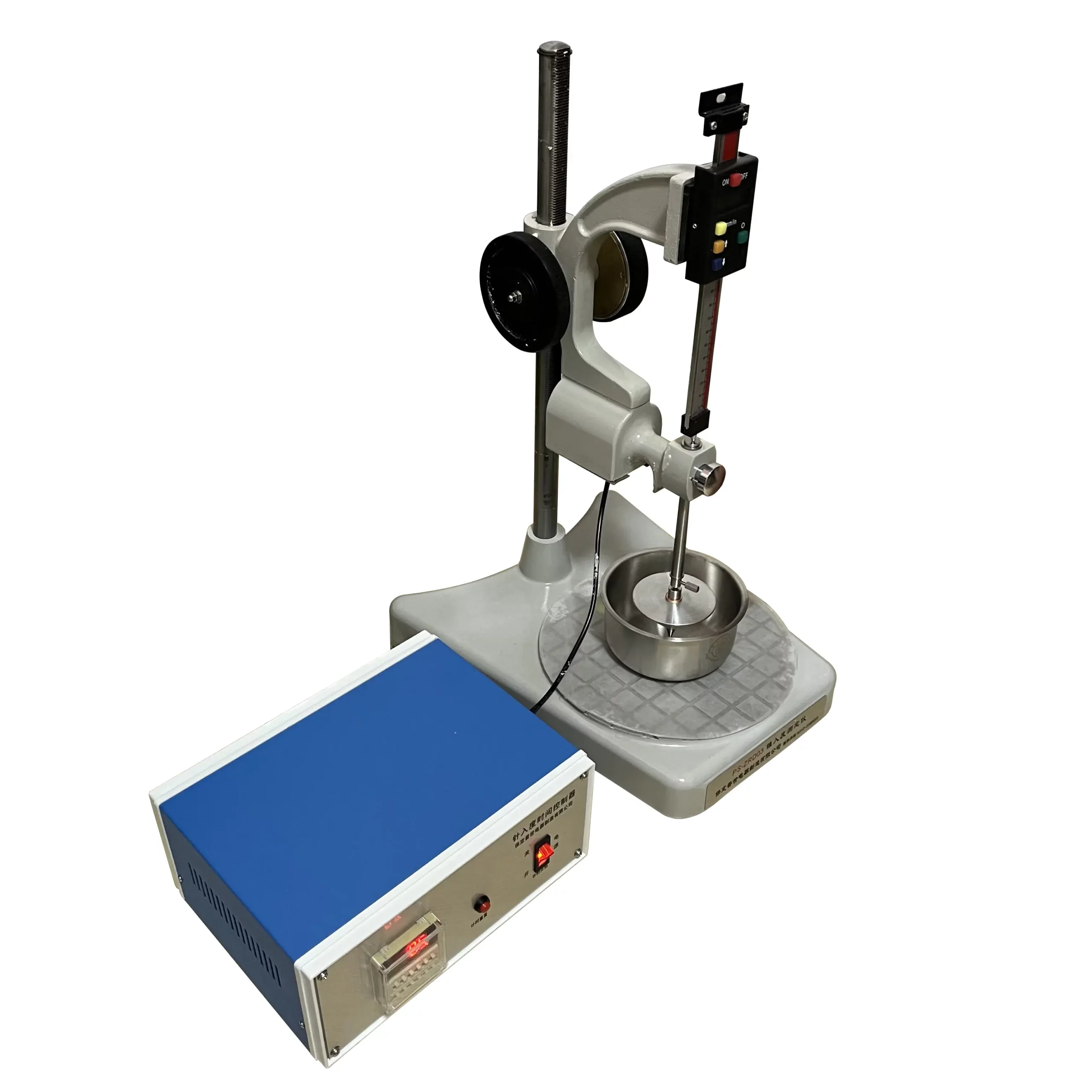

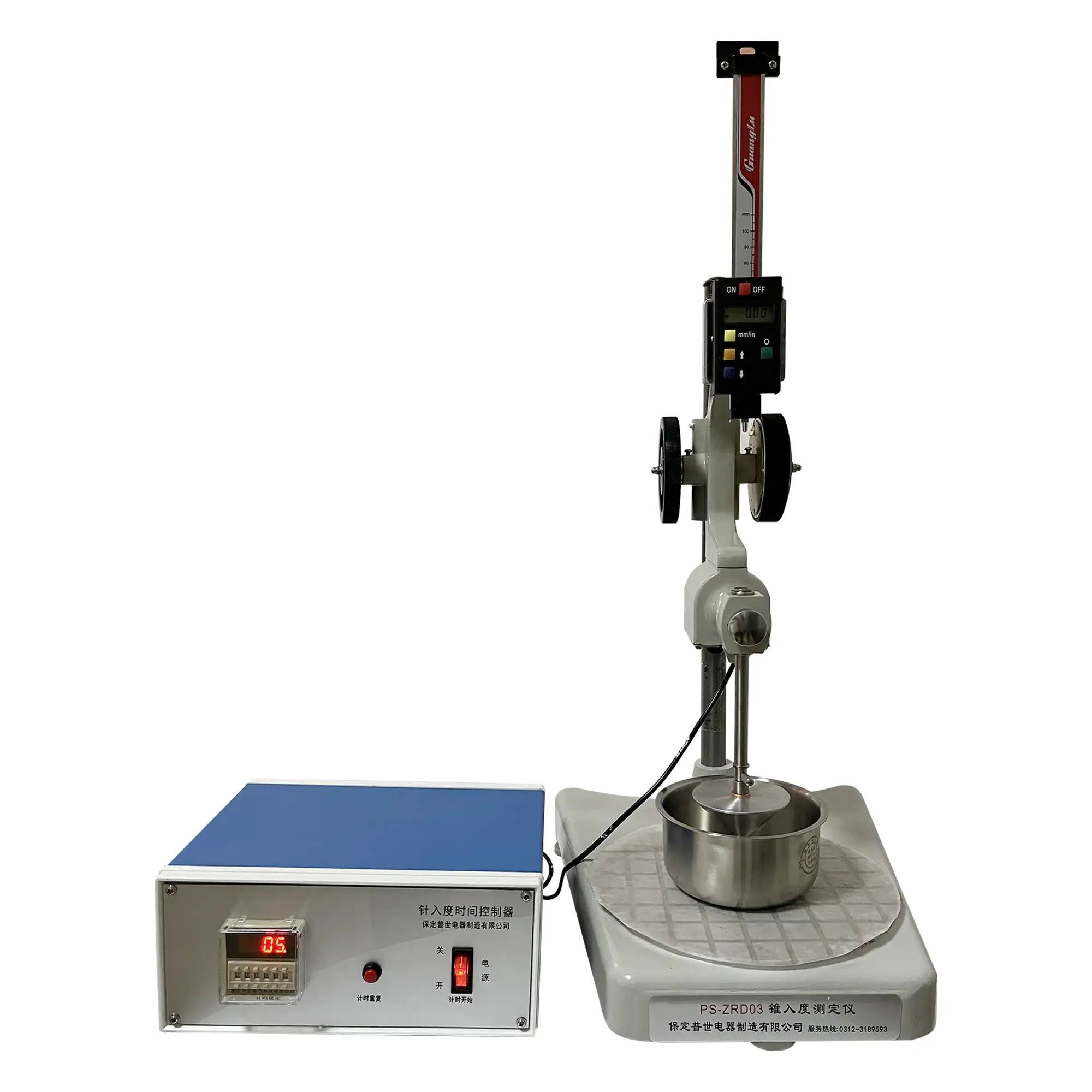

PS-ZRD03 Lubricating Grease Cone Lubricity Oil Penetration Tester Penetrometer Astdm 217

Short Description:

This instrument is designed and manufactured according to the relevant provisions of the national standard GB/T269 “Determination of Penetration of Lubricating Grease and Petroleum Grease”, which is suitable for measuring the penetration of various lubricating greases and petroleum greases. It can also be equipped with relevant standard needles for the material test of solid fine particles, powder, or colloid, frozen body, etc. and the inspection of cheese, sugar gum, butter, butter, fermented body and other food raw materials.

This instrument is also suitable for ISO2137-85 “Determination of Penetration of Grease and Petroleum Grease”; ASTMD217-82, IP50-79 “Determination of Penetration of Grease”

Model No.: PS-ZRD03

Send Email To Us

Product Detail

Product Description

1. Penetration indicator 8. Top of measuring rod

2. Coarse adjustment handwheel 9. Bottom of measuring rod

3. Fine adjustment handwheel 10. Manual release button

4. Upright column 11. Electromagnetic release button

5. Penetration table 12. Level bubble

6. Locking screw 13. Timer

7. Adjusting level screw

Precautions

1. Familiarize yourself with the instruction manual and test method standards before starting the machine.

2. When assembling the cone, pay attention to protecting the tip of the cone, and put a piece of foam on the table to prevent it from accidentally falling. If the cone tip is blunted by 1mm, it is equivalent to reducing the error of 10 cone penetration per test.

3. Do not rotate the quick handwheel and the fine-tuning handwheel at the same time with both hands, so as not to damage the gear mechanism due to forced rotation.

4. When it is necessary to adjust the position of the cone and the cone rod, hold the cone rod by hand and then press the release button, on the one hand to prevent the cone from accidentally falling down and damage the cone tip, and at the same time to avoid pulling out when the cone rod is locked, and wears the cone rod and the cone. Rod sleeve mechanism.

5. There is a weighted lead block in the cone rod to avoid loss.

6. The laboratory power supply should be well grounded. All power switches must be turned off after use.

7. If the instrument is not used normally or modified without authorization, it will not be able to enjoy the specified after-sales service.