The laboratory received the automatic insulation oil pressure tester, which items are suitable for acceptance?

Although as a customer, the ability to return this device after half a year is great, but after all, it is too laborious, so if possible, we can try to avoid this kind of return after half a year for one year. Here we briefly introduce a few ways:

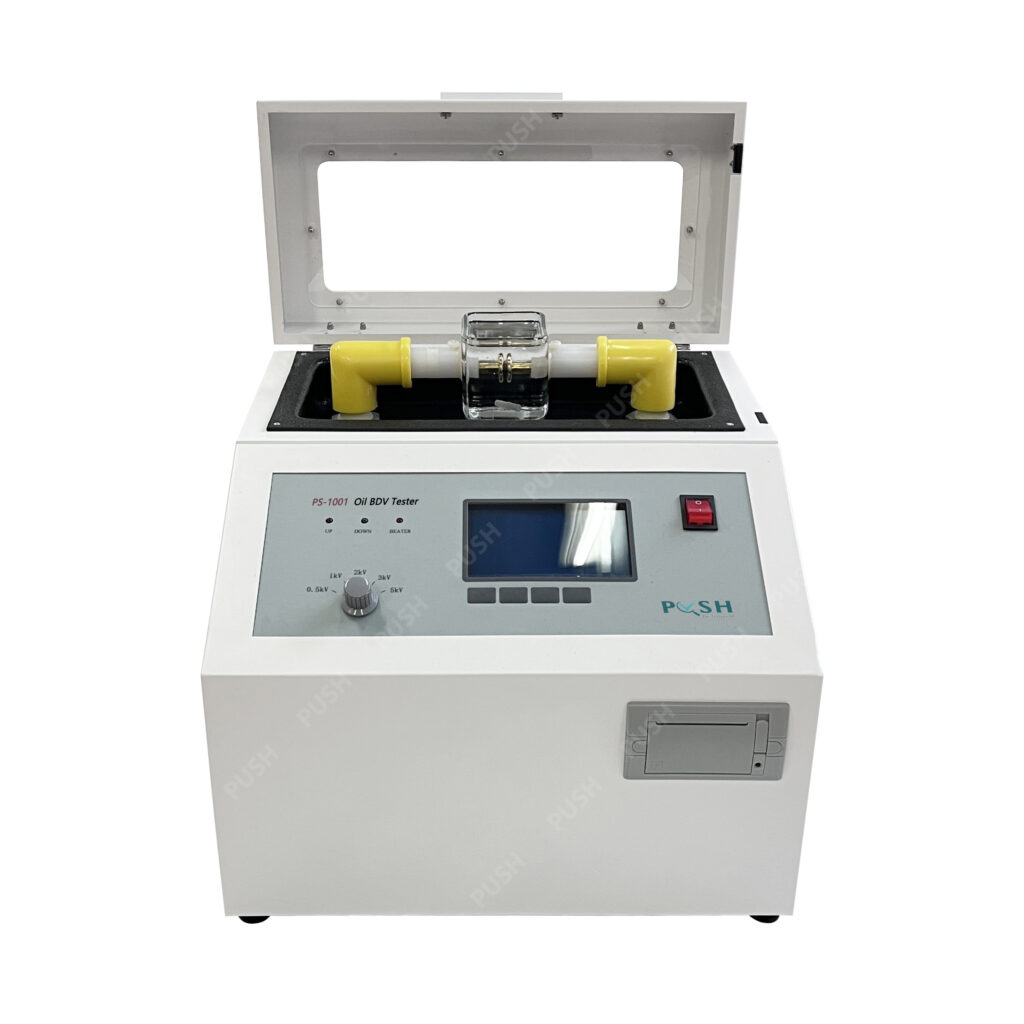

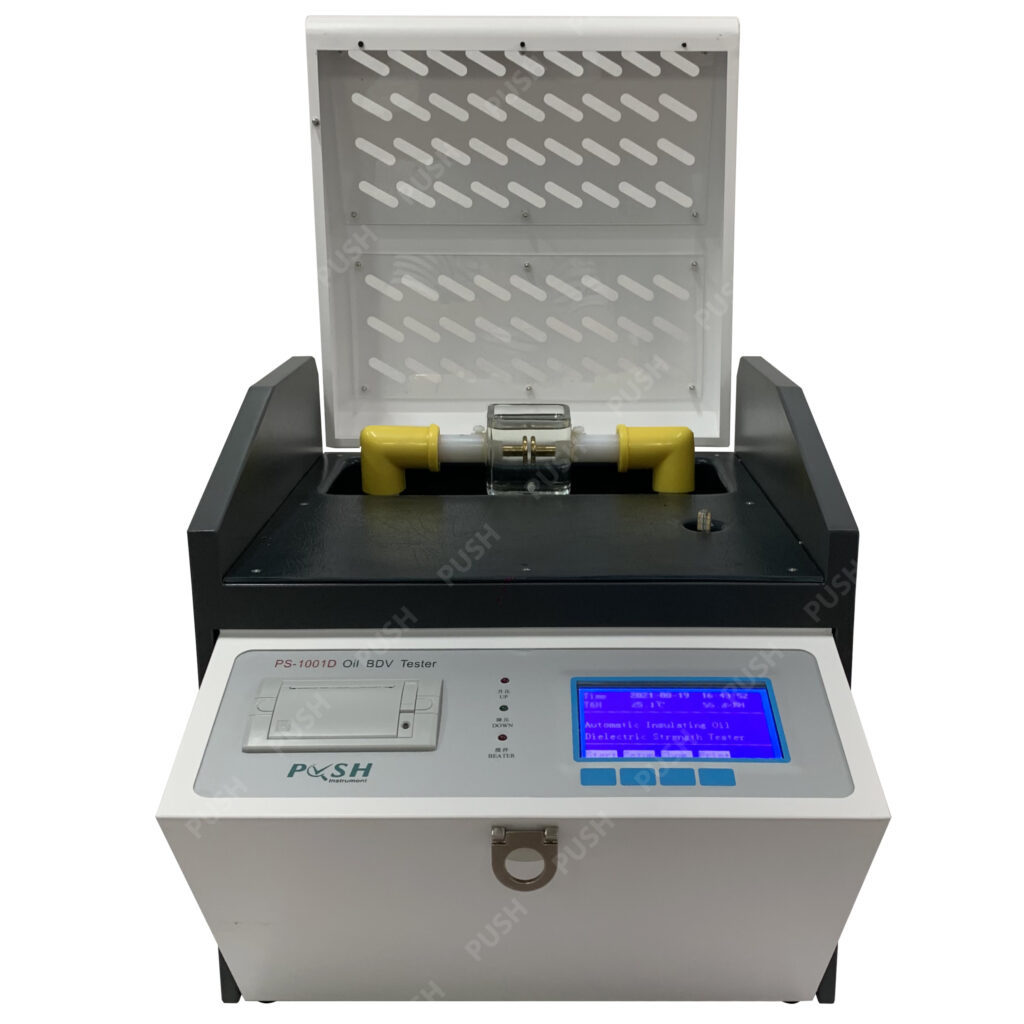

One is whether the product structure is still complete. If you haven’t seen many insulating oil withstand voltage testers in receipt, it’s hard to imagine such a requirement. The reason is that although the packaging of the insulating oil pressure tester is generally a wooden box, due to the weight of the product, some parts may be damaged during transportation. The general performance is: the casing is squeezed and deformed, especially the cover of the instrument, because the upper cover is mostly designed with plexiglass, so that the user can check the state of the oil cup during the test, and it is easy to be squeezed and broken. On the other hand, there are oil cups. The general structure of the oil cup is mostly glass, which is an accessory that is easily damaged due to excessive impact during transportation.

After checking the external structure, what about the internal structure? We were unable to open the case to see if it was complete. Of course, it’s not impossible, but some manufacturers of industrial products don’t allow it. Doing so can make it difficult to distinguish responsibilities. So most of them can’t test the internal structure after receiving the insulating oil withstand voltage tester, they can only check by other tests

Generally, it is possible to find out whether the internal structure of the equipment is damaged by energizing the insulating oil withstand voltage tester. The simple operation is to turn on the power after plugging in the power supply, and the startup screen displays normally. This is one aspect. On the other hand, in the insulating oil withstand voltage tester, the voltage regulating structure belongs to the only electromechanical matching part, which is easily damaged during transportation. So when you receive it, it’s a good idea to check the power supply and run the product. Specifically, trial operation can be carried out under the guidance of the manufacturer.

In general, the second part is necessary to avoid the method of leaving the bad rate until half a year later. The power-on test is actually a test without oil sample. Generally, some insulators are placed where the motor is placed. Don’t just empty test it, because it’s easy to have sparks running around, and while it won’t be a problem, it looks scary. The specific operation should be completed under the guidance of the manufacturer!