In the realm of electrical systems, ensuring the quality and reliability of insulating oils is of utmost importance. Breakdown voltage testing is a critical component of assessing the dielectric strength of these oils, which is vital for maintaining the integrity of electrical equipment. In this blog post, we will explore the significance of breakdown voltage testing and delve into the capabilities of BDV testing kits, including oil BDV test kits, to ensure the optimal performance of insulating oils.

Breakdown voltage tester, also known as dielectric strength testing, is a method used to determine the ability of insulating oils to withstand high voltage without experiencing electrical breakdown. Electrical breakdown occurs when the insulating material fails to resist the electric current, leading to potential damage to equipment and compromising the safety of the electrical system.

BDV testing kits play a pivotal role in conducting breakdown voltage tests on insulating oils. These kits are designed to provide accurate and reliable measurements of the dielectric strength of the oil, helping to identify any potential issues or degradation in its quality. Oil BDV test kits are particularly valuable in assessing the suitability of transformer oils, which are used for insulation and cooling purposes in electrical transformers.

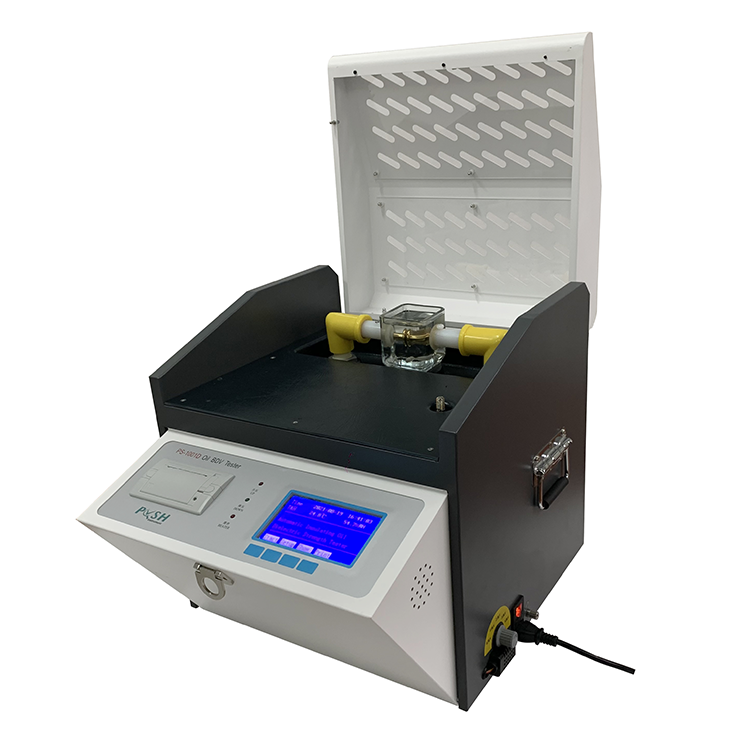

The oil BDV test kit typically consists of several components, including a high-voltage testing unit, a sample cell, electrodes, and a control panel. The high-voltage testing unit generates the desired voltage required for the breakdown voltage test, while the sample cell holds the insulating oil sample for analysis. The electrodes are carefully positioned within the sample cell to ensure accurate measurement, and the control panel allows the operator to monitor and control the testing process.

The breakdown voltage test itself involves applying an increasing voltage to the insulating oil sample, gradually raising it until an electrical breakdown occurs. The voltage at which breakdown occurs is known as the breakdown voltage or dielectric strength of the oil. This measurement is critical in determining the quality and effectiveness of the insulating oil for its intended application.

BDV testing kits offer several advantages in breakdown voltage testing. Firstly, they provide a portable and convenient solution for on-site testing, allowing for quick and efficient assessment of insulating oils without the need for sending samples to external laboratories. This saves time and cost while enabling timely maintenance and decision-making.

Secondly, BDV testing kit are equipped with advanced features and functionalities to enhance accuracy and reliability. These may include digital displays, data logging capabilities, and built-in safety mechanisms to ensure operator protection during the testing process. Some kits may also offer additional tests, such as moisture content analysis, to provide a comprehensive assessment of the insulating oil’s condition.

Regular breakdown voltage testing using BDV testing kits is crucial for preventive maintenance and early detection of potential issues in electrical systems. By monitoring the dielectric strength of insulating oils, operators can identify any degradation or contamination that may compromise the efficiency and safety of their equipment. Timely action can then be taken to rectify the situation, such as replacing or purifying the oil, thus preventing costly downtime and equipment failure.

In conclusion, breakdown voltage testing is a vital aspect of assessing the dielectric strength of insulating oils in electrical systems. BDV testing kits, including oil BDV test kits, offer a portable and efficient solution for conducting these tests on-site. By regularly performing breakdown voltage testing, operators can ensure the optimal performance and longevity of their electrical equipment, ultimately contributing to a safer and more reliable electrical system.