In high-voltage electrical equipment such as oil-immersed transformers, oil circuit breakers, and oil-filled cables, insulating oil is widely used and is often used for insulation and blocking work. However, during long-term use, the insulating oil of these electrical equipment will be disturbed by oxidation, high temperature, strong electromagnetic field, etc., and its insulation performance will gradually decrease or even disappear, making it unable to play an insulating role. To test the insulating oil to judge whether its insulating properties can still work normally, for this reason, electric workers have developed a dielectric strength tester for insulating oil.

The working principle of the insulating oil dielectric strength tester:

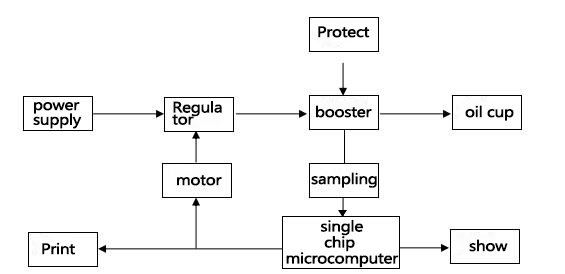

The AC high-voltage voltage of the oil test is obtained from the output of the voltage regulator through boosting. The hardware protection circuit can identify whether the oil sample is broken down. When the oil sample breaks down, the protection circuit automatically cuts off the input of the booster through the hardware. A stepper motor returns the regulator to zero. Both the lifting process of the voltage regulator and the boosting speed of the instrument are realized by the single-chip microcomputer controlling the rotation of the stepping motor according to the specific test program. During the entire boosting process, the voltage value between the electrodes in the oil cup is displayed in kV, and the voltage value at the moment before the breakdown occurs is taken as the breakdown voltage of a single oil test.

Its basic operation method is:

Preparation: The oil cup and electrodes need to be kept clean, and they must be filled with new transformer oil for protection during shutdown. After testing low-quality oil, it must be washed with solvent gasoline or carbon tetrachloride, and it can be used after drying.

The oil cup and electrodes should be inspected after one month of continuous use. Check whether the distance of the measuring electrode changes, and use a magnifying glass to observe whether there is any darkening on the surface of the electrode. If this happens, the distance between the electrodes must be readjusted and the electrodes must be wiped clean with a silk cloth. This work should also be done after long-term inactivity.

Sample loading: Before the test, the original insulating oil in the oil cup should be poured out, and the wall of the oil cup, electrodes and other parts should be cleaned immediately with the oil sample to be tested, and then slowly poured into the sample to avoid the formation of air bubbles. Put the oil cup on the high-voltage electrode in the fuel tank of the tester, and cover the fuel tank cap. Measure and record the oil sample temperature.

Experiment: Operate according to the instructions accompanying the instrument.