If you are going to choose the latest and new range of high-grade and advanced transformer oil breakdown voltage tester, it is better to keep in mind some essential points and focus on precautions that are associated with transformer oil breakdown voltage test.

● It is important to place or remove the oil cup. It should be done under the condition of power off.

● Don’t forget to check the distance between the electrodes. It is also important to clean the electrode surface with qualified transformer oil.

● Don’t forget to wipe the sampling valve and slowly open it – mainly when you are going to collect transformer oil and oil samples.

● It is also vital to flush the test cup for some more times and take the oil sample.

● Transformer oil is also required to be static in the certain mm to eliminate air bubbles. This quantity can be from 5 to 10 mm.

● Not to mention the speed of step up of oil tester that should not be faster. It should be about 3000v/s that is counted as appropriate.

● Voltage needs to reduce to zero before voltage turned off. Using high quality and advanced micro processors automatically is ideal way to complete the boosting, maintaining, stirring, static and calculating the testing process.

Above points will help you in providing assistance in choosing the right transformer oil breakdown voltage tester.

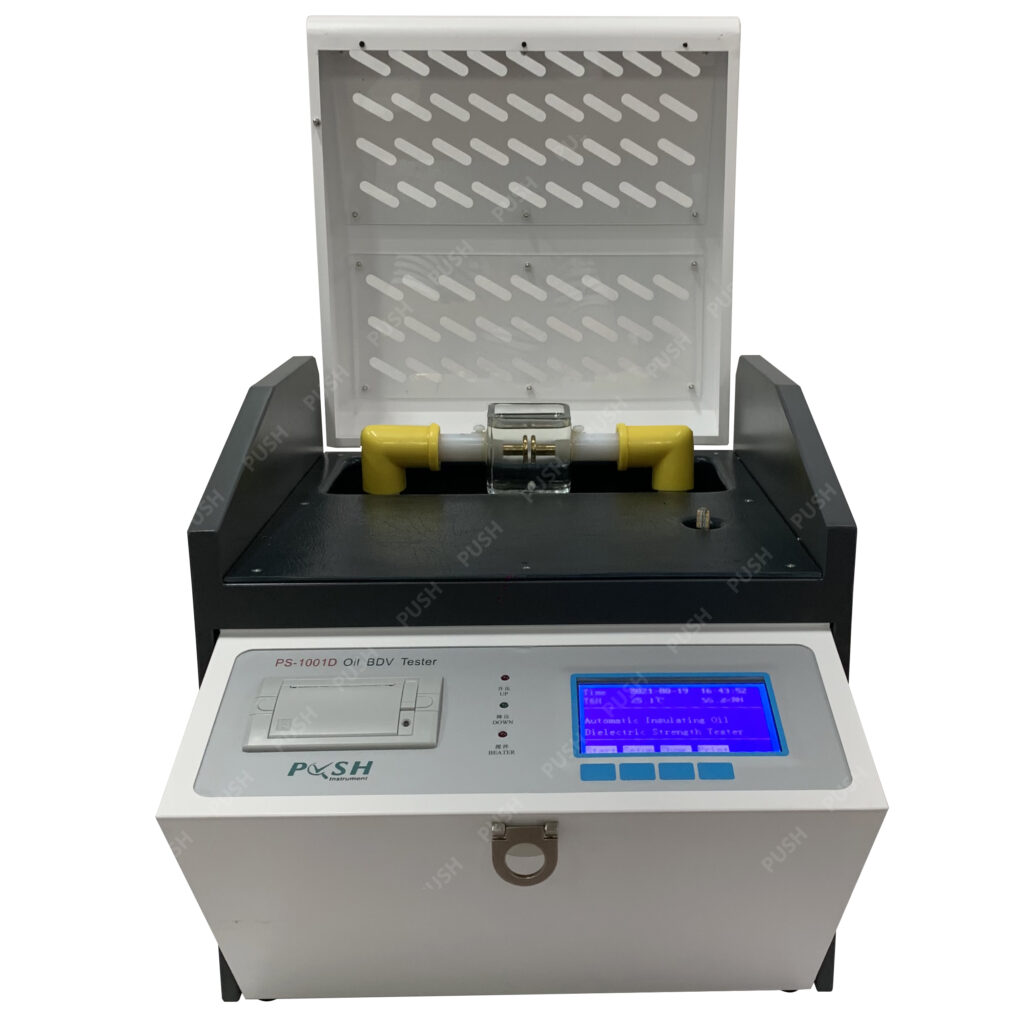

Our PS-1001D transformer insulating oil breakdown voltage tester meets the following conditions

● 5.4 LCD screen, Chinese (or English) menu is convenient for man-machine dialogue, with temperature, humidity measurement and clock display functions;

● The operation is simple, and the operations such as boosting, maintaining, stirring, standing, calculating, data storage and printing output are automatically completed;

● With power-off storage function, the test results can be automatically saved;

● With overvoltage, overcurrent, limit and grounding alarm functions to ensure the personal safety of operators;

● Unique waveform tuning function to eliminate the interference of harmonics to accurate measurement;

● The dual control of CPU and PLC is adopted to ensure the stable and reliable operation of the instrument;

● The device has 232, USB, Bluetooth ports and wireless transmission functions, which is convenient for data transmission with computers

Our PS-1001 series is one of your best choices