Flash point is a safety detection indicator of transformer oil during storage and use, especially the supervision of transformer oil in operation. Flash point is an essential item.The flash point of transformer oil refers to the temperature at which the mixture of oil vapor and air will flash on fire.

If the flash point drops, it means that volatile combustibles are produced in the transformer oil. These low-molecular hydrocarbons are produced by overheated transformer oil at high temperatures caused by local failures of electrical equipment.

By detecting the flash point, it is possible to timely detect the presence of overheating faults in oil-filled power equipment such as transformers. For newly filled equipment and maintenance and treatment oil, measuring the flash point can also detect the presence of light fractions. Oil products.

A flash point that is too low will directly lead to fires in electrical equipment. Therefore, there are strict flash point control indicators in the new oil standards of transformer oil. At the same time, the flash point of the transformer oil in operation must also be strictly controlled.

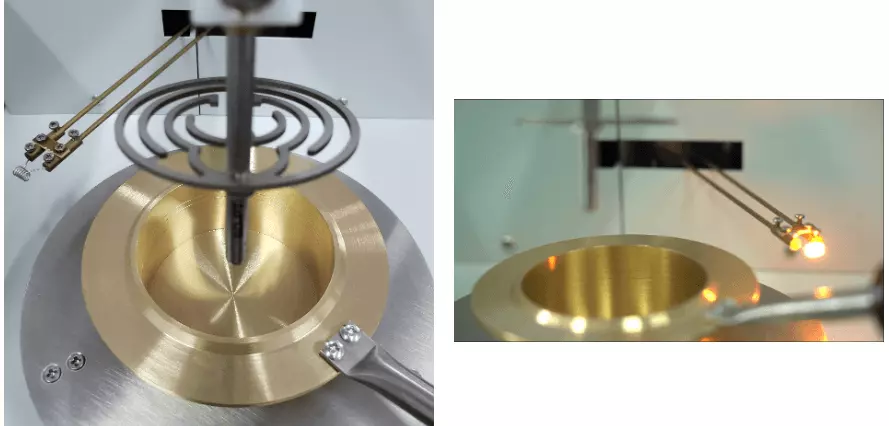

Transformer Oil Flash Point Analyzer

The transformer oil open flash point tester is used to measure the flash point of open cups for petroleum products under specified conditions. Transformer oil opening flash point tester is widely used in petrochemical, electric power, railway, aviation, shipbuilding and scientific research departments. The instrument has the characteristics of stable and reliable operation, easy operation and accurate measurement. It is the best equipment for oil analysis and quality testing.

Features of Transformer Oil Flash Point Analyzer

1.China Transformer Oil Flash Point Analyzer adopts color LCD large screen display, full Chinese human-machine dialogue interface, capacitive touch screen, and has prompt menu and guided input functions for parameters such as pre-value temperature, sample label, atmospheric pressure, test date, etc.

2. Simulation tracking displays the function curve of temperature rise and test time. It has a Chinese incorrect operation software prompt modification function, and is equipped with a parameter prompt function such as test date and test time.

3. Automatically correct the influence of atmospheric pressure on the test and calculate the correction value.

4. Differential detection and automatic correction of system deviations.

5. Scanning, detecting, and printing data are completed automatically, and the test arm automatically rises and falls.

6. Two ignition modes: electric ignition and gas ignition, forced air cooling.

7. Able to perform ignition point testing and fire extinguishing operations with the lid closed.

8. With instrument self-test function.

9. You can manually sweep the fire at any time to check the flash point of the sample.

10. The hysteresis temperature can be adjusted at any time to expand the measurement range of the instrument.

Push,China’s Cheap Transformer Oil Flash Point Analyzer can cater to buyers various needs without high fee.

Production standard of China Transformer Oil Flash Point Analyzer

The fully automatic closed flash point tester is designed and produced in accordance with standards such as GB/T261-2008, GB/T21615-2008, ASTM D93 and EU REACH regulations. It is a new instrument for measuring the closed flash point of petroleum products.

Custom Astm D93 Flash Point Test Equipment meaning and use:

- Flash point temperature is a measure of the tendency of a specimen to form a flammable mixture with air under controlled laboratory conditions. It is just one of many properties that must be considered when assessing a material’s overall flammability hazard.

- Flash point is used in transport and safety regulations to define flammable and combustible materials. One should consult the specific statute involved for precise definitions of these classifications.

- These test methods should be used to measure and describe the response characteristics of materials, products or components to heat and ignition sources under controlled laboratory conditions and should not be used to describe or evaluate the fire hazard or fire risk of materials under actual fire conditions. products or components. However, the results of these test methods can be used as elements of a fire risk assessment that takes into account all factors relevant to the fire hazard assessment for a particular end use.

- These test methods provide the only closed cup flash point testing procedures for temperatures up to 370 °C (698 °F).